Quality

Woodland Plastics is ISO 9001:2015 certified manufacturer. With a Commitment to Quality, Woodland delivers thermoset molded parts and components on time, and that meet stringent product and engineering quality standards. Through continuous improvement, teamwork, a sense of urgency, and a strong focus on technology improvements, Woodland is dedicated to exceeding customer expectations. By implementing multiple layered quality assurance processes throughout its manufacturing process and utilizing key tools within ERP real-time manufacturing software, Woodland ensures delivered parts meet tolerancing and drawing specifications. Woodland’s ERP system allows for historical and real-time data to accurately record, track, monitor, and analyze product and manufacturing data and quality metrics including in-process inspections, layered process audits, work instructions, document control, and customized predictive and preventive maintenance schedules based on each product line’s requirements.

At the heart of Woodland Plastics’ commitment to quality is preventive and corrective actions, which isolate each issue and/or concern, and ensures all potential non-conforming parts are quarantined, recorded, and evaluated to eliminate the root cause of a defect or quality issue. Woodland leverages IQMS as its ERP real-time software system to direct and record quality functions including management inspection data, process audits, production and processing metrics, work instructions, and document control.

Quality Process:

- Woodland Plastics’ quality process starts with the commitment made by each employee.

- Continuous improvement and training is the focus of everything we do.

- Internal weekly and quarterly meetings detect non-conformances and prevent future non-conformances.

- All issues and concerns are met with urgency.

- Multiple performance indicators are monitored, including production, on-time shipment and delivery, scrap, and non-conforming part statistics.

- Data is constantly recorded and analyzed to ensure parts are produced at the highest quality.

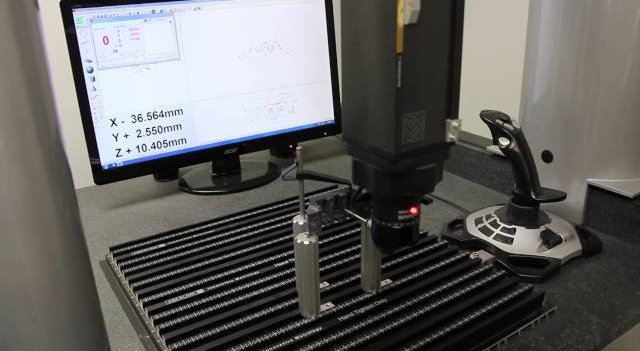

Quality Spotlight – Coordinate Measuring Machine (CMM)

With a coordinate measuring machine, Woodland Plastics is able to:

– Check multiple features of a part on different planes, angles, & radii.

– Compare physical part dimensions with 3D CAD data.

– Provide measurement data with high precision and accuracy.

– Automate secondary measuring operation, limiting labor costs.