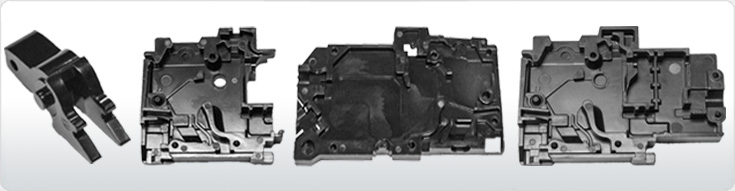

Molded Circuit Breakers

Woodland Plastics has experience molding a variety of circuit breaker components including covers, bases, cases, and handles in both thermoset BMC and phenolic molding materials. Circuit breaker components are molded in multi-cavitation molds and then deflashed and inspected prior to shipment to customer assembly plants. Depending on specific requirements, some circuit breaker components also include a post-baking operation after molding for additional cure.

Utilizing thermoset materials into molded circuit breakers enhances safety and provides high protection against electrical current, voltage, and electrical arc/track in addition to offering heat and corrosion resistant properties.

Project Highlights for Molded Circuit Breakers

- Product Description

-

Molding, Deflashing, and Post Baking of Electrical Circuit Breaker Components

- Molding Process

-

Injection – Thermoset

- Material

-

Bulk Molding Compound (BMC), Phenolic

- Molding Machine

-

150T, 300T, 500T

- Color

-

Black

- In-Process Inspection

-

SPC, Gauge Testing

- Industry for Use

-

Residential and Commercial Circuit Breaker

- Standards Met

-

Customer supplied Drawing