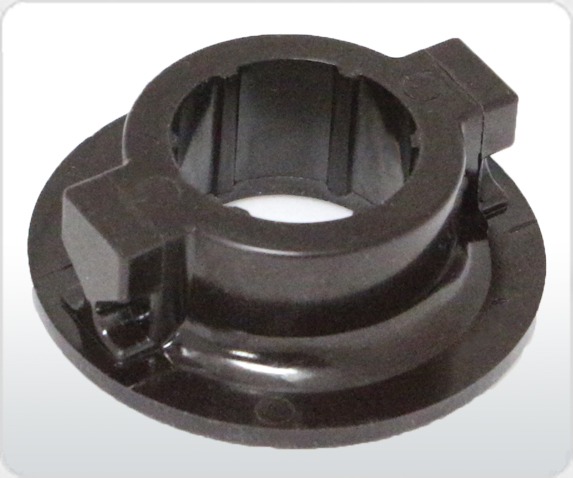

Governor Spool for Electrical Motor Industry

Woodland Plastics partnered with a manufacturer of electric motors to mold these governor spools used within electric motor applications. Using a 250-ton thermoset molding machine, Woodland Plastics molds the parts in an 8-cavity tool using injection molding process.

Because these parts require high dimensional stability and strong electrical properties, the material chosen to mold these parts is a graphite-filled phenolic resin from Plenco. After molding, the finished parts are post-baked in an oven for final curing, and then deflashed in an automated wheelabrator before being dimensionally inspected by quality and then shipped to a customer plant in Texas.

Project Highlights for Governor Spool

- Product Description

-

Governor spool used within electric motors

- Molding Process

-

Injection – Thermoset

- Material

-

Plenco 04582 Brown – Phenolic

- Equipment Used to

-

8-Cavity

- Molding Machine

-

250-Ton Thermoset Injection Molding Machine

- Color

-

Brown

- In-Process Inspection

-

Dimensional Inspection

- Estimated Part Weight

-

12.5 grams

- Industry for Use

-

Electrical

- Standards Met

-

Customer supplied Drawing

- Product Name

-

Governor Spool