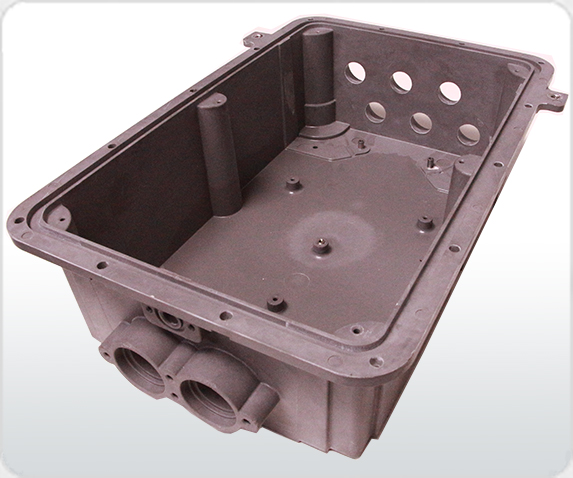

Enclosure for Electrical Industry

Woodland was contacted by a customer to discuss our metal-to-thermoset conversion experience pertaining to an existing metal enclosure product assembly the customer had. After reviewing part requirements and geometries, Woodland was able to partner with the customer to convert the existing aluminum parts to thermoset, drastically reducing part weight and unit pricing for the customer over the metal assemblies through part consolidation and also increasing product performance with corrosion resistant properties thermosets provide. The part weight of the injection-molded thermoset enclosure was reduced from the prior aluminum design by nearly 2 lbs.!

These thermoset enclosures are injection molded in a 500T thermoset injection molding machine with molded in bracket inserts, and are then tapped and inserted with threaded brass inserts post-mold. A mating lid to the enclosure is also thermoset injection molded before being digitally printed with the customer’s logo and identification.

Project Highlights for Enclosure

- Product Description

-

Outdoor Electrical Enclosure and Lid

- Molding Process

-

Thermoset Injection

- Material

-

MB 2000-20 Bulk Molding Compound (BMC) Polyester

- Equipment Used to

-

Single Cavity

- Manufacture Part

-

500-Ton Thermoset Injection Molding Machine

- Overall Part Dimensions

-

Length: 14″

Width: 9″

Height: 4″

- Color

-

Gray

- Special Processes

-

Enclosure features molded-in bracket inserts, post-mold tapping, post-molded inserts, and the Lid features a secondary digital printing process.

- Estimated Part Weight

-

Enclosure is 1,410 grams, and Lid is 590 grams

- Industry for Use

-

Outdoor Electrical

- Standards Met

-

Customer Supplied Drawing

- Product Name

-

Enclosure & Lid