What is a Thermoset?

Thermosets are synthetic composites that strengthen when heated but cannot successfully be remolded or reheated after initial molding or heat-forming. Molded thermosets offer excellent dimensional stability within high temperatures and challenging environments. Thermoset parts are resistant to corrosion, UV exposure, and aggressive chemicals such as oils and automotive fluids, making thermosets an ideal material choice for part assemblies exposed to outdoor elements and automotive applications. In electrical applications, thermoset parts exude exceptionally strong electrical properties of insulation and dielectric strength, along with low arc and tracking resistance. Thermoset materials protect the integrity of a molded part and internal electrical components and wiring throughout a product life cycle as parts will not degrade or disfigure under electrical exposure that thermoplastic molded part may experience.

Thermoset molding materials include Bulk Molding Compound (BMC), Phenolic, Epoxy, and Diallyl Phthalate (DAP). Bulk Molding Compounds are unsaturated polyesters and vinyl esters. Thermosets can be injection, compression, injection-compression, or transfer molded. The main molding difference between thermosets and thermoplastics is that thermosets are molded into a preheated or hot mold at around 350F. The thermoset resin meeting the hot mold causes a chemical reaction, and gives the molded part its strong end properties. A thermoplastic on the other hand is molded into a cooled mold to form the molded parts.

Understanding Thermoset Plastics

With an array of material property benefits, molded thermoset parts are used in a variety of customer end-markets and applications that require a strong, durable material capable of withstanding aggressive elements. Thermosets will not degrade with exposure to certain chemicals, oils, and automotive fluids. In electrical applications and assemblies, thermoset parts protect internal components with superior dielectric strength and electrical insulation. In outdoor applications, thermoset components remain durable even in wide-ranging weather conditions including exposure to heavy sunlight and UV, rain, sleet or snow. Whether a product application functions in Alaska or Arizona, thermosets remain a preferred material choice of engineers and designers for challenging applications requiring heat-stable components. Cost-wise, thermosets are advantageously priced per pound against similarly-performing engineered thermoplastics.

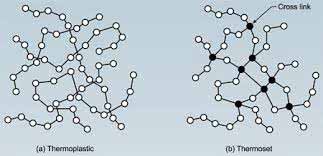

In scientific terms, a thermoset monomer must have three or more reactive ends, with its molecular chains crosslinking in three dimensions. Post-molding, thermosets have virtually all molecules interconnected with strong, permanent, physical bonds which are not heat reversible. Thermoplastic monomers on the other hand, only have two reactive ends for linear chain growth.

In layman terms, molding or curing a thermoset is like cooking an egg or baking a cake. Once an egg is dropped into boiling water and cooked, it cannot revert to its original physical state as a yoke. Similarly, after thermosets are molded, it cannot be ground up and reprocessed or remolded.

Benefits of Thermoset Plastics

- Corrosion and Steam Resistant

- High Dielectric Strength

- Excellent Chemical and Dimensional Stability

- High Strength-to-Weight Ratio

- Excellent Thermal Properties

- Low Creep/Shrink

- Heat Resistant

- Superior Thermal Insulation