Technology

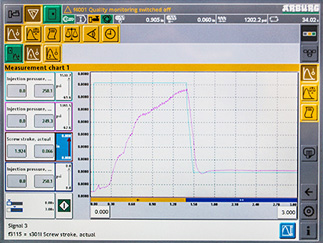

As a technology-driven manufacturer, Woodland Plastics provides integrated solutions to serve OEMs with thermoset molded components and assemblies that meet stringent product and customer specification requirements. Woodland Plastics leverages technology through real time ERP software, which records, monitors, and stores manufacturing data and visibility into each step of a manufacturing process. Woodland’s ERP software system is tied to all molding machines and auxiliary equipment; and gives Woodland the ability to analyze production data either in real time or within a historical date range or data set. Woodland Plastics uses its ERP system, IQMS, in various functions of its business, including production data collection and monitoring, job and program work instructions, document control, layered process audits and quality inspections, predictive and preventive maintenance, estimating and costing, and employee and job-specific training.

Woodland Plastics is always exploring improvements to existing processes and equipment with investments in molding machines, auxiliary equipment, inspection technology, and automation solutions. Whether a product requires zero-defect shipments, 100% camera inspection, or special manufacturing requirements, Woodland Plastics can develop a manufacturing and inspection process to meet customer and product quality and delivery standards.

Utilizing IQMS, a plastics-industry leading, real-time ERP software system, gives Woodland Plastics the ability to:

- Monitor the entire manufacturing process

- Monitor real-time production and scheduling

- Manage document control

- Use predictive maintenance for tooling and machines

- Set up Just-In-Time (JIT) product delivery

- Develop project/asset management tools.

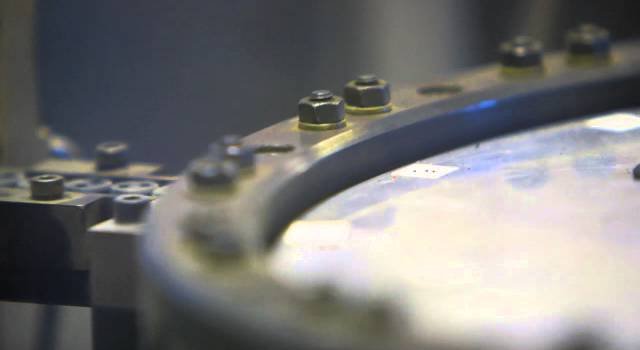

Technology Spotlight – Automated Degating Machine

By investing in a custom-built degating machine, Woodland Plastics:

– Offers an automated deflash operation, increasing throughput.

– Reduces labor costs & process variation by eliminating operator variation.

– Tracks production with ERP software for real-time productivity data.

– Tracks real-time data for advances in predictive & preventive maintenance of the machine.

Technology Spotlight – Automated Vision Inspection System

Woodland Plastics implemented this automated vision inspection system for a 42-cavity lighting component program in order to:

– Provide a cost-efficient, automated secondary inspection process to 100% inspect parts.

– Inspect large-volume parts that would be costly to inspect manually.

– Eliminate operator inspection error due to automated repeatability.

– Measure a variety of dimensions & part characteristics that may be difficult to inspect manually.