Engineering Services & Tooling Design

With over 20 years’ experience in the thermoset industry, Woodland Plastics offers support in engineering, tooling, and material selection to bring our customers’ projects to market. Whether looking to improve upon an existing part, designing a new product assembly, or converting a former metal or thermoplastic part to a thermoset part; engineers and designers leverage Woodland’s expansive thermoset expertise and knowledge base to alleviate pain points and ensure a successful product launch.

By providing integrated manufacturing solutions, Woodland Plastics can assist with tool and material sourcing and selection, to molding and secondary operation assembly requirements. Our customers rely on Woodland’s thermoset experience to enhance manufacturability of their products and reduce unnecessary costs at all stages of product development and manufacture.

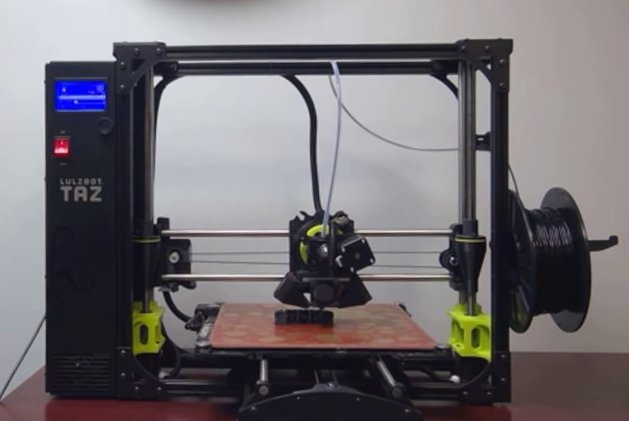

Technology Spotlight – 3D Printing

As a technology-integrated custom thermoset molder, Woodland Plastics offers 3D printing services for expanded prototyping capabilities and engineering support, assisting customers to:

– Review Fit, Form, & Feel of a Product or Assembly Design

– Provide a Rapid, Low-Cost Prototyping Option

– Review Multiple Product Designs Simultaneously

Engineering Services and Tooling Design Capabilities

- General Capabilities

-

Consulting

Design

Tooling for manufacturingTooling for prototyping

Repair

- Product Designed

-

Molds

ToolingFixtures

Secondary Operation Tools and Equipment

- Engineering Capabilities

-

Computer Aided Design (CAD)

Electrical

HydraulicsMechanical

Pneumatic

- Additional Services

-

Engineering

Design

Product Development

FixturesMold Maintenance

Tooling

Manufacturability

Project Management

- Quality

-

ISO 9001:2008 Certified

- Manufacturing Systems

-

Enterprise IQ: Manufacturing ERP Software System running real time production data

- Industry Focus

-

Appliance

Automotive

ElectricalLighting

Energy

- Professional Affiliations

-

UL Certified

Society of Plastics Engineers (SPE)Tooling Manufacturers Association (TMA)

- File Capability

-

AutoCAD

Solid Works

PhotographsPDF

MS Office Suite